HSE Management System

OGDCL has always contributed to the environment where it works in and contributed to the welfare of the people of the area also. We ensure that our products are supplied to the market, consumers and other stakeholders only after having properly processed i.e. WITH MINIMUM (ALLOWABLE) POTENTIAL FOR POLLUTION. In addition to the contemporary solutions, modern processes are being carried out as company policy which shows sustainability towards protection of the environment, our workforce and assets. OGDCL has developed and implemented the HSE System to improve its HSE performance and ultimately to reduce the adverse impact of its operations, activities, and services on 3Ps i.e. people, plant, and planet. Our HSE System complies with the latest revisions of international standards ISO14001, ISO45001, OHSAS18001, ISO 31000, Guidelines of The International Association of Oil & Gas Producers (now IOGP and formerly known as OGP) and OSHA’s Process Safety Management (PSM) Guidelines; its scope covers:

- Engineering / construction operations;

- Exploration, including seismic techniques and geological surveys;

- Drilling of exploratory wells and geological services;

- Drilling and development of production wells; and

- Treatment of oil and natural gas to yield marketable products.

The system describes the way our company is managed with respect to our stated HSE policies and strategic objectives. The HSE system ensures that the safety critical activities of the company in Pakistan are identified controlled and that measurements are made and reported so as to enable monitoring of overall performance and identification of areas for improvement.

This HSE System addresses the organizational structure and responsibilities of people, the management of resources and documentation required for sound safety performance for all OGDCL activities. The document provides the framework for planning of work activities, which include existing operations, management of changes and developing hierarchy of procedures both for the normal as well as abnormal conditions. The general policy statement is followed by the procedures to outline how the general system-policy is implemented

This HSE System addresses the organizational structure and responsibilities of people, the management of resources and documentation required for sound safety performance for all OGDCL activities. The document provides the framework for planning of work activities, which include existing operations, management of changes and developing hierarchy of procedures both for the normal as well as abnormal conditions. OGDCL’s HSE System is divided into Nine (09) Elements and Thirty One (31) Procedures, corresponding to the Main Sections & Subsections of ISO14001, ISO45001, OHSAS18001, ISO31000 standards and OSHA’s PSM guidelines.

Revision of OGDCL's Integrated HSE System Manual (Rev#08)

- Preamble Integrated HSE System

- Terms&Definitions OGDCL Integrated HSE System

- Context OGDCL Integrated HSE System

- Leadership OGDCL Integrated HSE System

- Planning OGDCL Integrated HSE System

- Support OGDCL Integrated HSE System

- HSE Short Awareness Session (Training) Planner

- Emergency Drill Planner

- Toolbox Talk Program

- Toolbox Talk Assessment (OGF-HSE-007A)

- HSE Short Awareness Session Attendance Record

- HSE Short Awareness Session Evaluation Form

- Training Certificates (standard format as used by OGTI)

- Product Safety Data Sheet (PSDS)

- External Environmental Complaint (EECS) Sheet

- Inter office Memos Format (standard format as used by various Departments)

- Master List of Documents

- List of External Documents

- Document Change Request (DCR) Form

- Distribution Log

- Master List of Records

- Operation OGDCL Integrated HSE System

- Operational Controls – Plans; Procedures

- Operational Controls – Work Instructions

- Operational Controls – Inspection and Maintenance Programs

- Operational Controls – Calibration Plans

- Cold Work Permit

- Sour/Hot Work Permit

- Electrical Work Permit

- Confined Space/Vessel Entry Work Permit

- Radiography Work Permit

- Excavation & Civil Work Permit

- Working at Height Permit

- PTW Toolbox Talk

- Vehicle Entry Permit

- Energy Isolation Log Sheet

- Power Isolation Slip

- Safety System Defeat Certificate

- Permit Log

- Onsite Waste Management Plan

- Section Waste Register

- Waste Consignment Note

- Waste Disposal Log

- Vehicle Inspection Checklist

- Wellsite Handing Over Taking Over Checklist

- QC Checklist Treatment & Restoration of Pits

- Journey Management Plan

- Performance Evaluation OGDCL Integrated HSE System

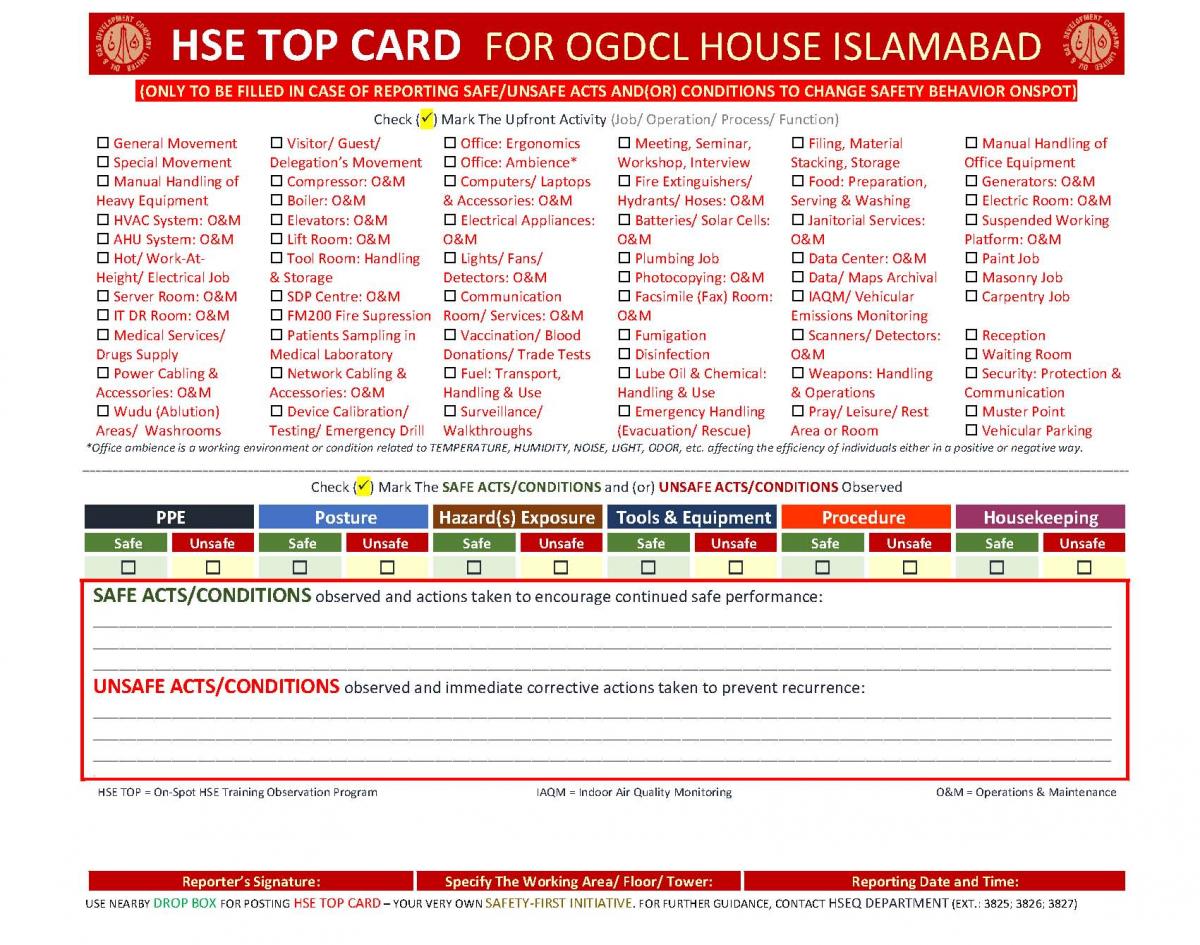

- TOP HSE Cards

- Health & Hygiene Monitoring Plan

- Safety Monitoring Plan

- Environmental Monitoring Plan

- Occupational Health Assessment (Trade / Fitness Test) Plan

- HSE Monthly Report

- List of Internal (Qualified) HSE Auditors

- Annual Internal HSE Audit Planner

- Internal HSE Audit Plan

- Standardized HSE Audit Checklist

- Internal HSE Audit Report

- Agenda of Location HSE MRC Meeting

- Minutes of Location HSE MRC Meeting

- Improvement OGDCL Integrated HSE System

For implementation of the operational controls at unit/ sub-unit levels, we have developed three OGDCL’s Safety Handbooks as follows – workforce's handy workplace safety documents which have been distributed to all workforce members at seismic parties, drilling rigs, and operating fields as important ingredient in the implementation of an effective workplace safety management program. The information in the handbook is derived from reliable international & local sources including regulations, statuary laws, treaties and guidelines.